Overview

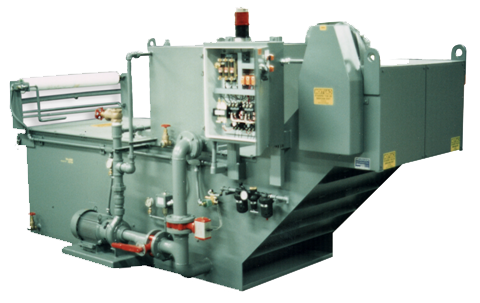

Polytech's conventional vacuum filters provide reliable automatic filtration of water based machine tool coolants. Vacuum filters are suitable for:

- Coarse or fine solid contaminants

- Coolant flow rates from 20 to over 600 gal/min

Applications

- Creepfeed Grinding

- High Efficiency Deep Grinding

- Surface Grinding

- Internal & Centerless Grinding

- Abrasive Belt Grinding

- Cutoff Saws

- Honing, Lapping, & Superfinishing

- Diamond & CBN Abrasive Machining

- Broaching, Hobbing, Trepanning

- Gear Hobbing

- Boring, Drilling

- Chucking, Milling

- Turning, Lathes, Machining Centers

How it Works

Conventional vacuum filters utilize the difference in pressure between the dirty coolant tank at atmospheric pressure and the lower pressure created by the centrifugal pump's suction characteristics. This forces coolant through a non-woven filter fabric. The filter pump supplies clean, filtered coolant to service.

These systems use a robust sludge conveyor to transport spent filter media and solid contaminants from the filter. A clean coolant reservoir supplies coolant while the filter media indexes. This ensures there is no interruption in coolant supply to the machine tool(s).

Specifications

Conventional vacuum filters can typically provide:

- 5 PSI differential pressure across the filter media

- Ensure coolant flow rates and contaminant loading per square foot far exceeds the capability of gravity type filters

The non-pressurized design is more reliable than pressure filters. Pressure filters have complex media handling and sealing needs while the vacuum system does not. Vacuum filters provide automatic, self-regulated operation. These offer easy, less labor intensive maintenance than cartridge or bag filters which require manual filter changes.

Design and Customization

Polytech Vacuum Filters are widely accepted by sophisticated industrial users. We offer effective consistent filtration that is essential to meeting process quality objectives. Polytech Vacuum Filters can be designed for installations such as

- A pit for gravity fed contaminated liquid entry

- A floor mounted unit to accept flow from overhead or sump station piping

Speak to one of our engineers about your application's specific requirements.